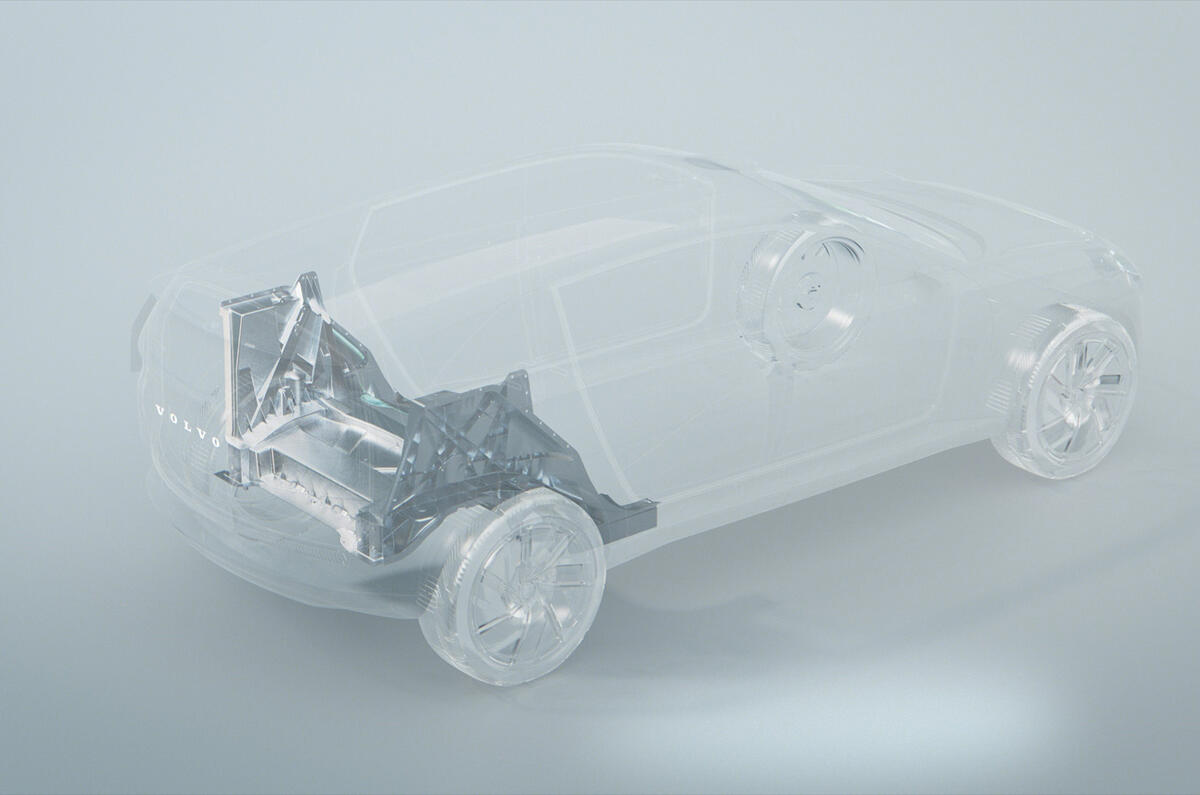

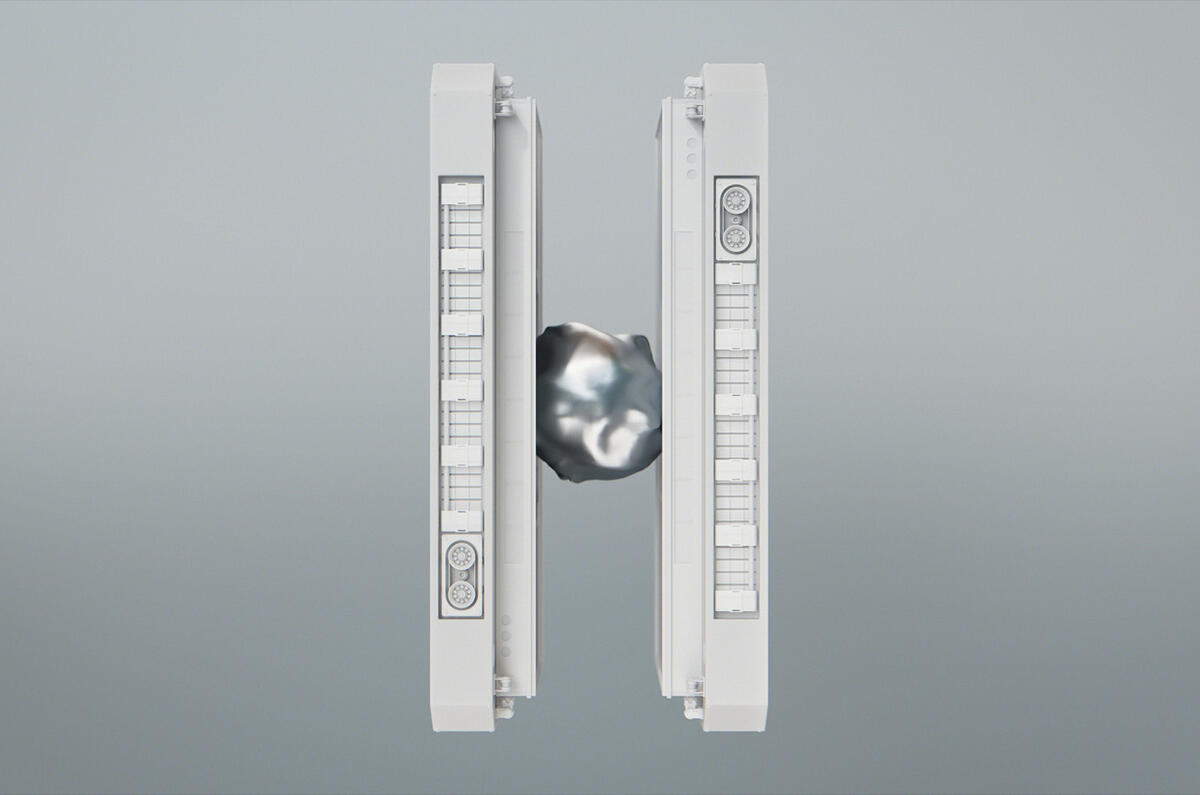

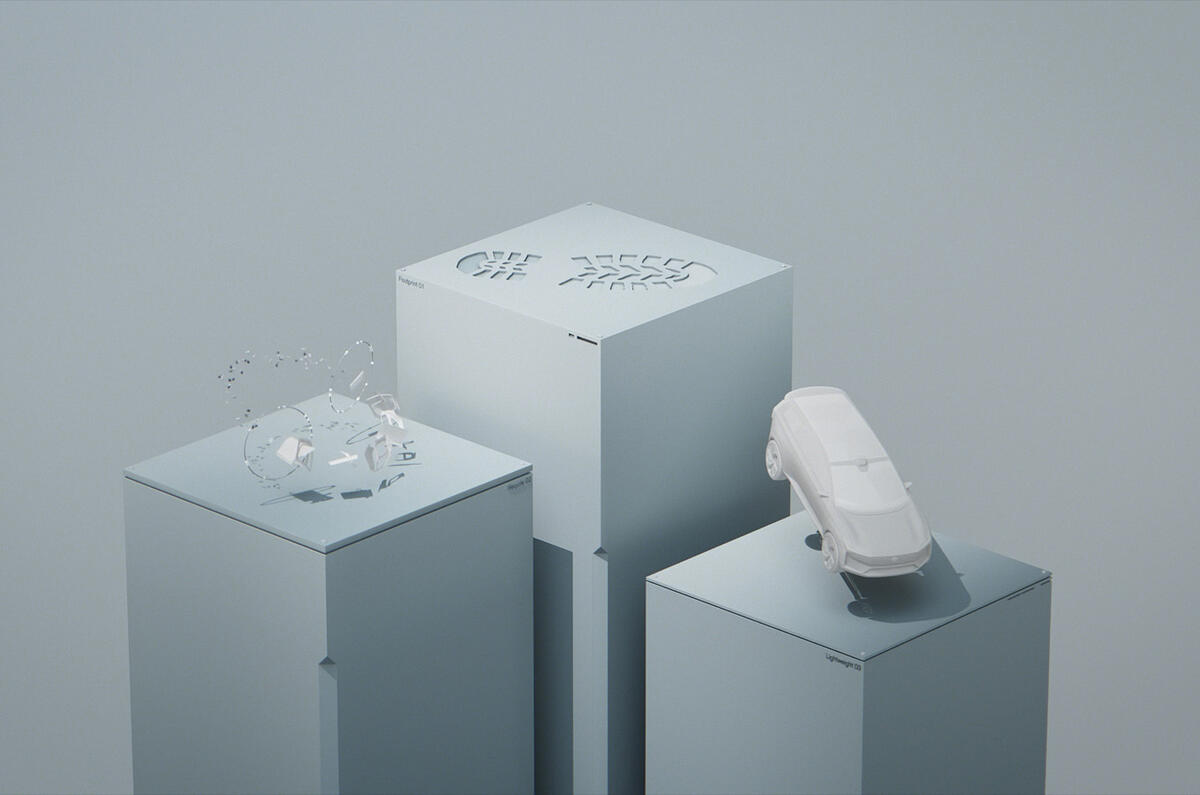

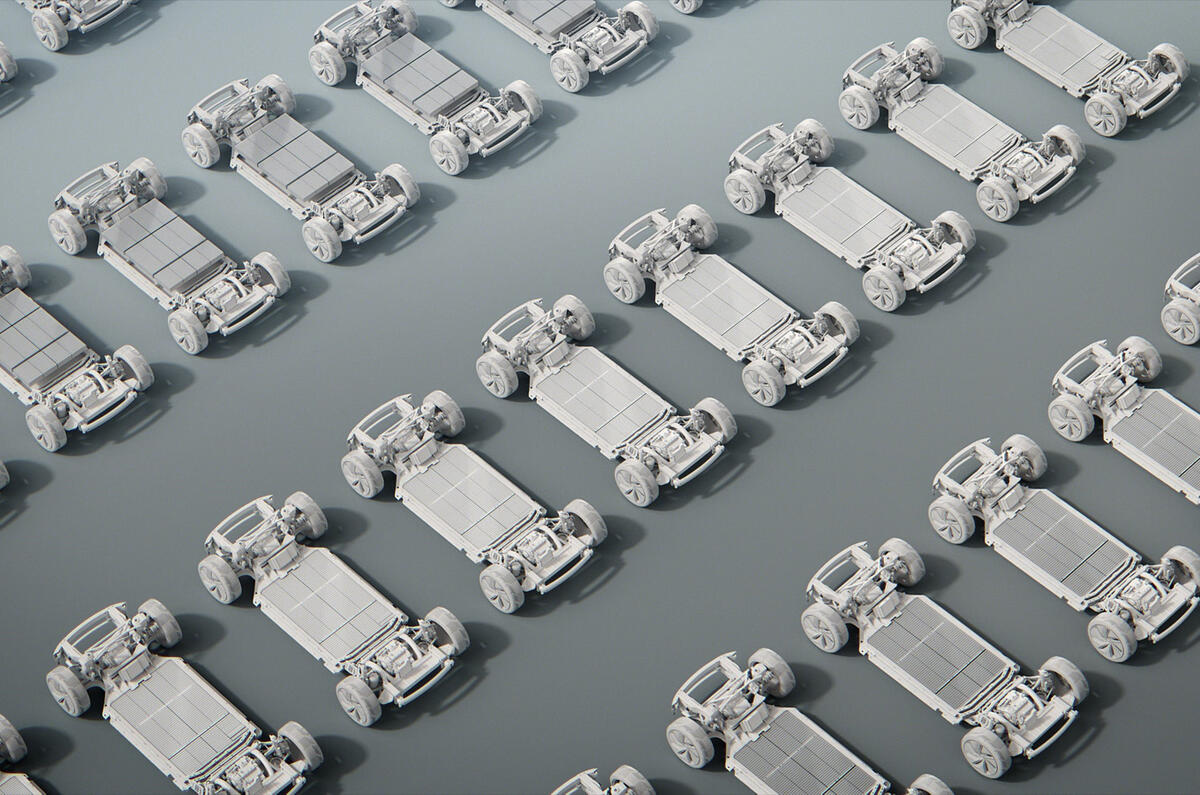

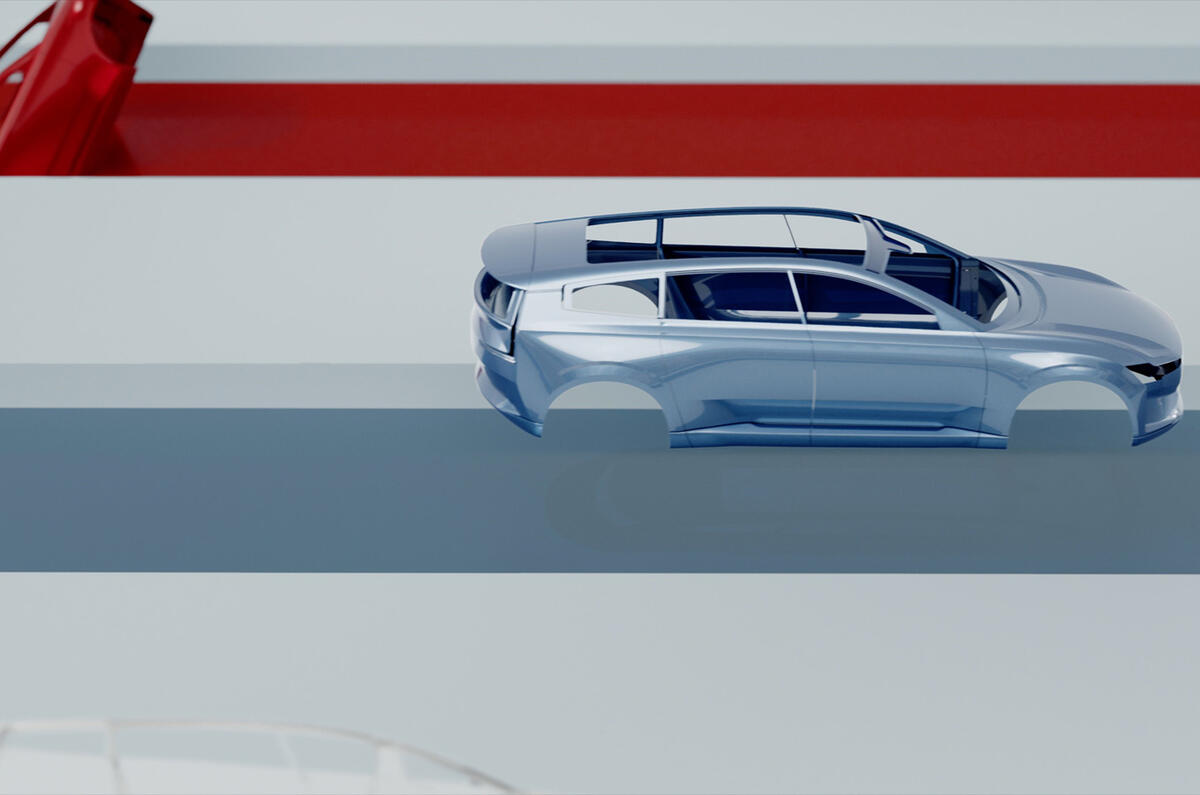

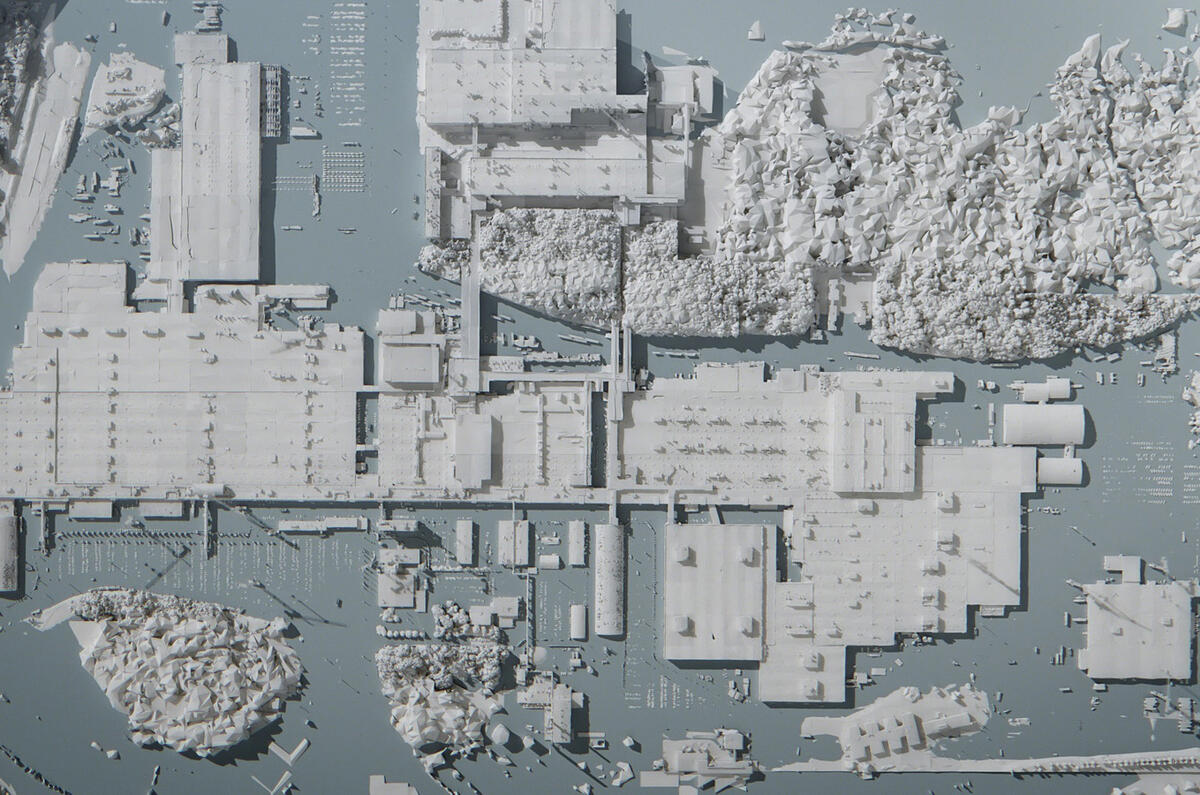

Volvo will invest more than £800 million to upgrade its largest factory to prepare for its shift to all-electric vehicle production, introducing a battery assembly plant and new technology to create aluminium parts.

The firm, which will go EV-only by 2030, will over the next few years upgrade its largest plant in Torslanda, Sweden, focusing on sustainable technologies and manufacturing processes.

Join the debate

Add your comment

...another Chinese incursion.

This time it's right on our doorstep.

Stop with the asian hate. #endrasism

Replace 100 parts with 1 may be cheaper for the manufacturer, but will it be cheaper for the consumer or insurance companies in the event of an accident? I suspect not.