The Kwik Fit British Touring Car Championship’s tightly controlled technical regulations are a key reason it regularly produces such exciting racing – and ensuring its ultra-competitive teams play by those rules is a tough job.

The BTCC has a small group of technical experts at each race to make sure that happens. This year, they’ve got a new home: the TOCA Technical Centre, a newly finished truck unit that travels to every race with all the equipment needed to run a BTCC race weekend. That includes all of the technical kit, the BTCC’s bespoke signage, event branding and even photographer Jakob Ebrey’s stepladder.

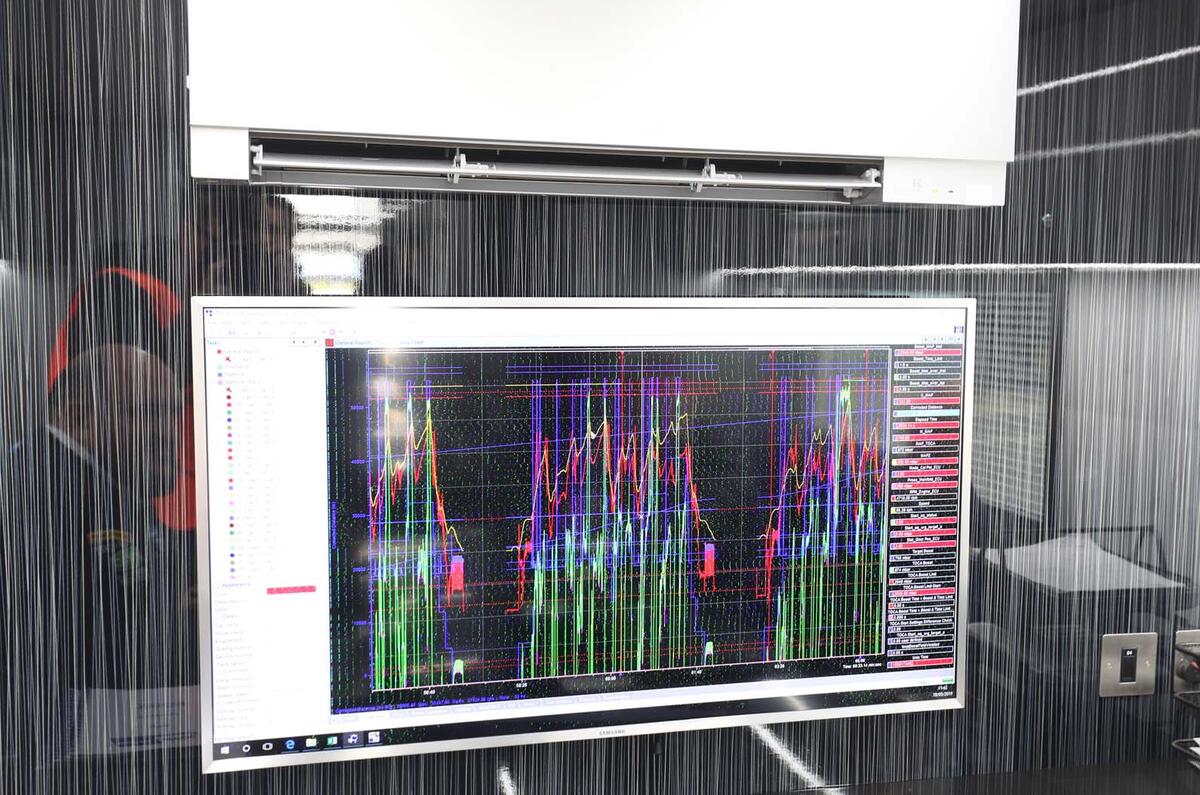

Once the equipment is set up, the truck effectively becomes the technical team’s mobile command unit, where they can analyse data and samples in order to police the rules.

The mammoth truck replaces two smaller vehicles and has, technical director Peter Riches says, taken the championship “to the next level”. For example, it has an in-built radio unit and mast, used to run the communications network. Previously, that unit had to be assembled on top of the tallest building at each circuit.

At a cost of around £250,000, the Hopkins Motorsport-prepared unit has been fitted with state-of-the-art kit, including Getrac laptops and tablets. It means Riches, his son Sam and Phil Danbury, both BTCC technical commissioners, and their team instantly have the information they need – and the evidence that makes winning arguments with teams easier.

Here’s what goes on inside it.

In-car footage

Every car has an on-board CCTV camera so that stewards can rule on any incidents and footage saved to memory cards is downloaded and collected here. ITV is also provided with the footage when needed.

Add your comment