White lines, yellow lines, rumble strips… We take them for granted but the material they’re made from is designed to operate in some of the most challenging conditions imaginable. They’re replicated in laboratories like the one tucked at the back of Hitex International, a leading manufacturer and applier of road markings based in Ellesmere Port, Cheshire.

Here, Steve, one of the company’s most experienced chemists, mixes, heats, weighs and generally tests road marking formulations to destruction like some bearded wizard of the white lines.

In one corner of the lab is a portable skid resistance machine. It has an arm fitted with a calibrated rubber slider designed to pass over a sample of road marking. As it does so, it brushes it, generating a skid resistance value or SRV. A white centre line should have an SRV of 45+.

Close by it is a retroreflectometer for testing the night and daytime reflectivity of road marking samples. Beads derived from recycled glass provide the reflectivity.

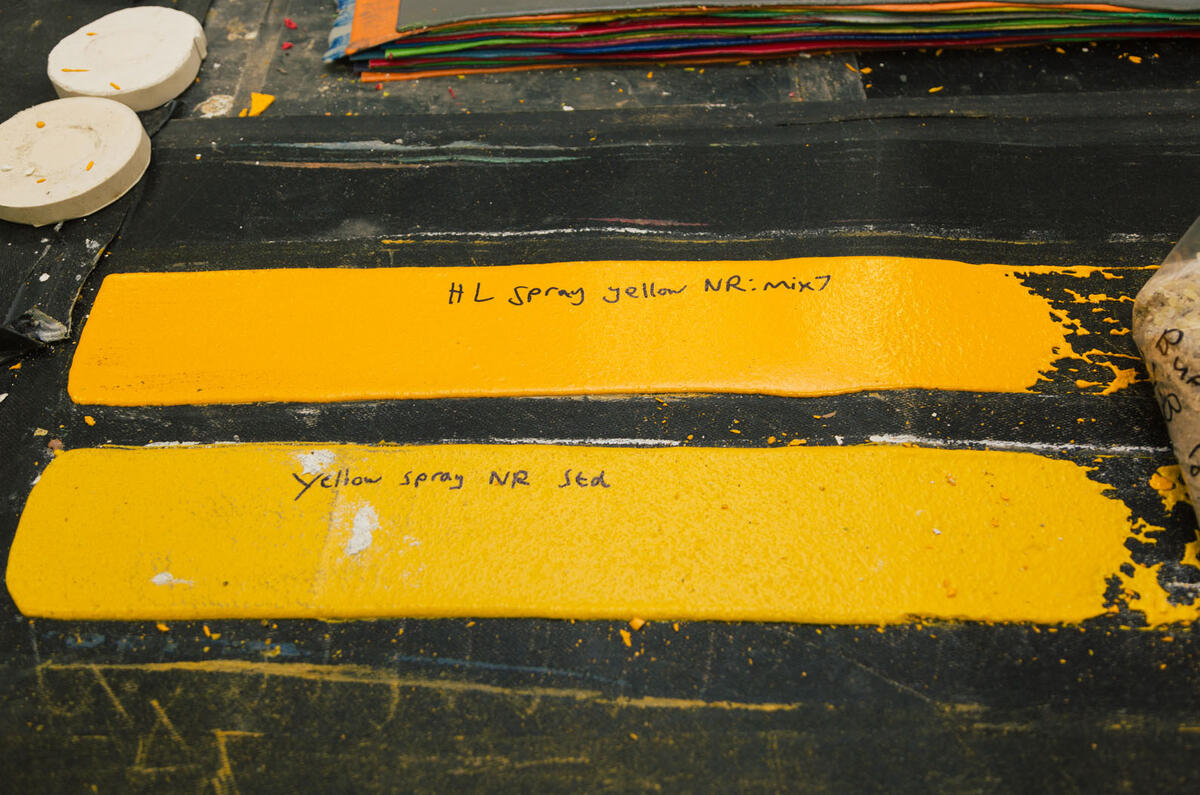

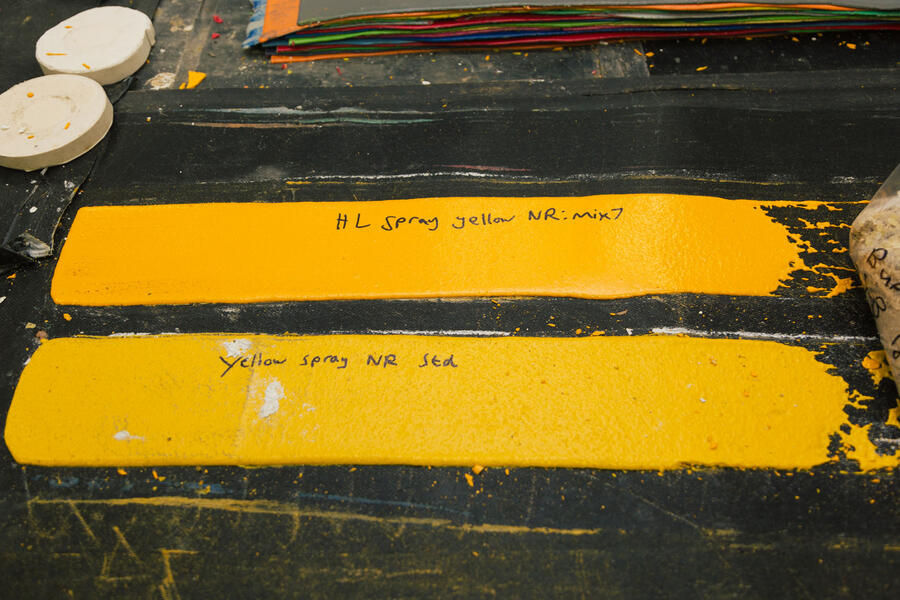

Elsewhere in the lab, Steve (he won’t reveal his surname – “Confidential,” he says, only half jokingly) tests the colour fastness of road markings. He tells how Hitex saved the day on the M3 when Highways England noticed the orange-painted emergency refuge areas on the smart motorway were bleaching.

“We developed a more UV-stable pigment in the lab for them,” he says, proudly. I don’t bother asking for the recipe. Confidential, probably…

Easily the simplest but most ingenious piece of equipment in his lab, though, is the softening point tester. A glass beaker is filled with a calibrated heat-transfer liquid in which a circular disc of solid road marking material is suspended. A steel ball is then placed on the surface of the disc. The temperature at which the ball sinks through the material is the material’s softening point. It’s an important number to know, especially for road marking applications in extreme heat; for example, in Bahrain, where the road surface can easily reach 90deg C.

Join the debate

Add your comment

Taken for granted.

Road markings, we take them for granted, something that’s there and never wondered about, now they’re more important because of the new tech in cars to make cars safer, i never wondered about them till I read about the processes that go into making and applying the stuff onto the roads.

Catseyes

Good line marking is important but on dual carriageways and motorways having decent Catseyes is invaluable. With them you don't really need street lighting.

I know there's a lot more

I know there's a lot more traffic on the roads nowadays, but what ever they use for white lining only seems to last about 5 minutes before its worn away. Still, I suppose they want to keep their business turning over.