The premise of the Dunlop MSA British Touring Car Championship is that it contains cars that trackside fans can relate to. A quick glance at the car park at Brands Hatch’s opening rounds this Sunday will demonstrate the fact - the cars on the grid are the cars that people use in everyday life.

But the race machines themselves are the product of thousands of man-hours and detailed reworking which is more usually associated with the very highest levels of the sport.

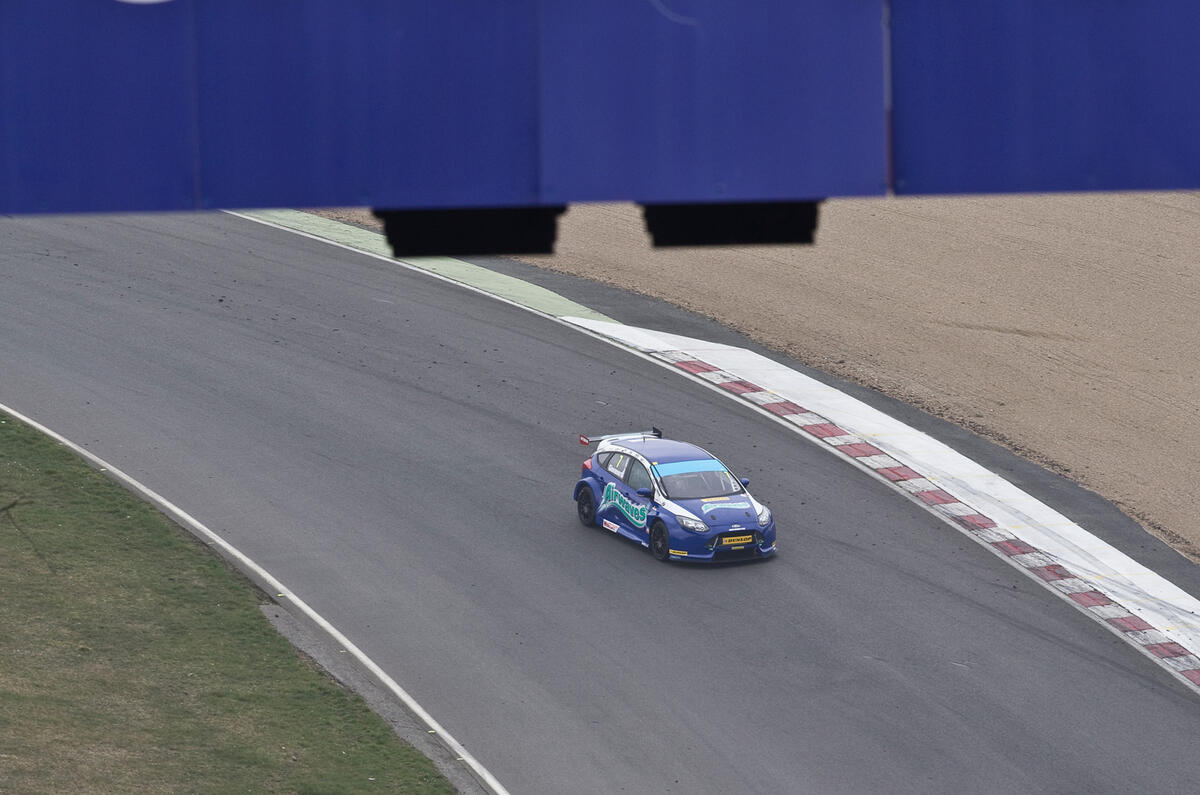

Airwaves Racing is a multiple race-winning team in the BTCC, and it is likely to be a leading player in this season’s competition because it has recruited double champion, Italian Fabrizio Giovanardi, to handle its Ford Focus ST.

The outfit is based just a few miles from the gates of Brands Hatch in Kent, and its HQ is where the race machine takes shape.

Team manager Oly Collins explains: “Some teams might just buy a bodyshell but we prefer to buy a complete road car and go from there, because there are several parts that we can carry over. Things like the door rubbers, some of the wiring loom, the light clusters, doors and bonnet will all come in useful for us later on.

“The first job is to strip the car back down to the bare bodyshell, and then we take it to be acid-dripped. We do this so that the paint is stripped away and it also makes it a better surface to weld things to. It removes all the sealant from the other parts of the shell and other materials that are put in to sound proof the vehicle. It literally is back to the bare metal.”

Once the car is returned to the team after this process, there is more refinement to be done before the hard work can begin on turning it in to a race machine. More of the vehicle’s basic features have to be removed.

“You have to de-bracket the car,” says Collins. “We will remove the fixtures for the seat belt, for example, and the roof lining. We will pare everything back, and that has the benefit of lightening the vehicle as well.”

Then the precision work starts. When a road car comes off the production line, the theory is that everything is identical. But in the motor racing world, where millimetres count, even that has to be double-checked.

“We will put the car on a jig, which has the precise measurements we want for the suspension pick-up points and things like that because we need repeatability. Everything has to be exactly the same from race car to race car,” says Collins. “The road cars are generally very good in terms of being exact, but when you are dealing with racing cars we go to a different level of precision.”

Once the crew is satisfied that the car is to the exact dimensions it requires, then the first of the race-bred parts can begin to take shape.

The British Touring Car Championship mandates a number of controlled parts, determined by the series organisers, which are common across all race machines. These are called the Next Generation Touring Car rules (NGTC) and were introduced in 2011 to help curb the spiralling costs in tin-top competition in the UK.

Collins says: “We have to install both the front and rear subframes, which are standard NGTC parts built by a firm called GPRM. We strip the bodyshell back to the bulkhead and then put the front subframe in, which will also have been on a jig to make sure that it is absolutely accurate. Things like this are vital, because a wrong measurement here will affect the handling of the entire machine.

Join the debate

Add your comment

Just like rally cars and the

The old days of Touring cars in the 60's were much more realistic,Jag 3.4's,Lotus Cortina's etc,they never cost this much,nor did my Avenger Tiger Rally car! Sure they were slower than now but things have gotten way out of hand for the "Man in the Street"["Joe Public"] whatever you want to call him.Sad in a way.