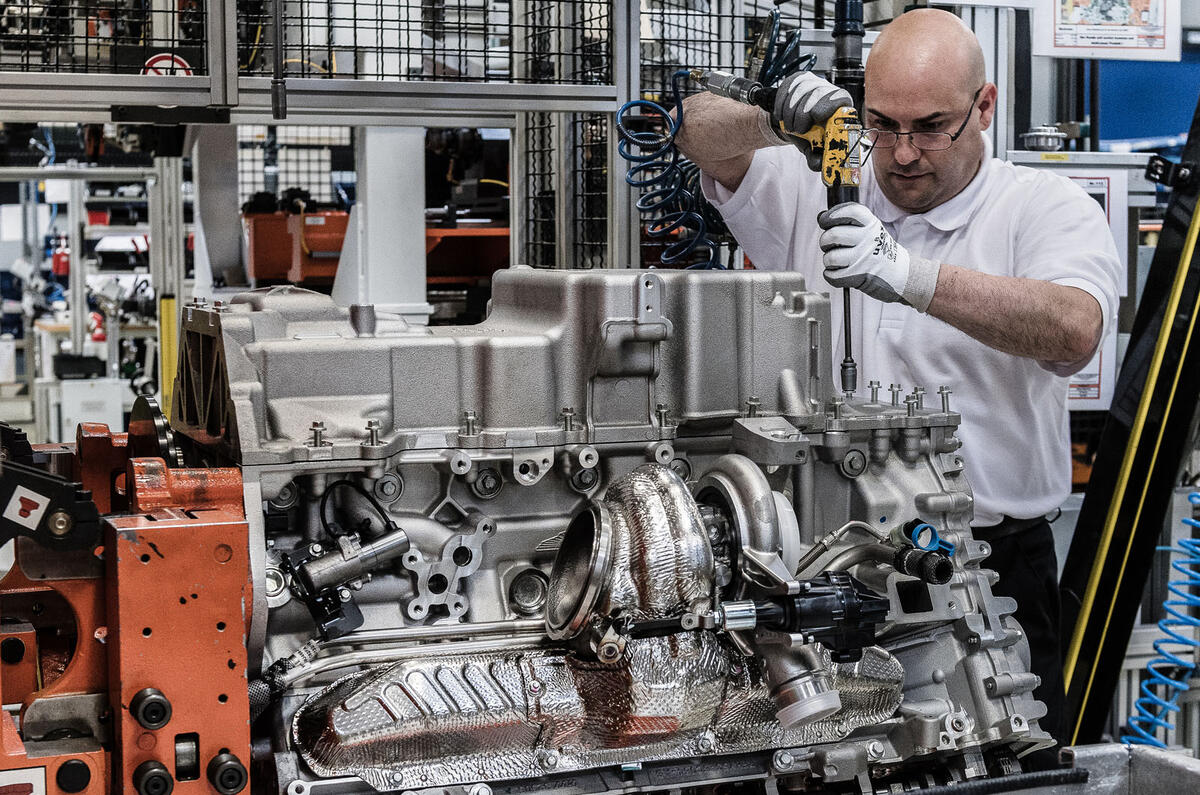

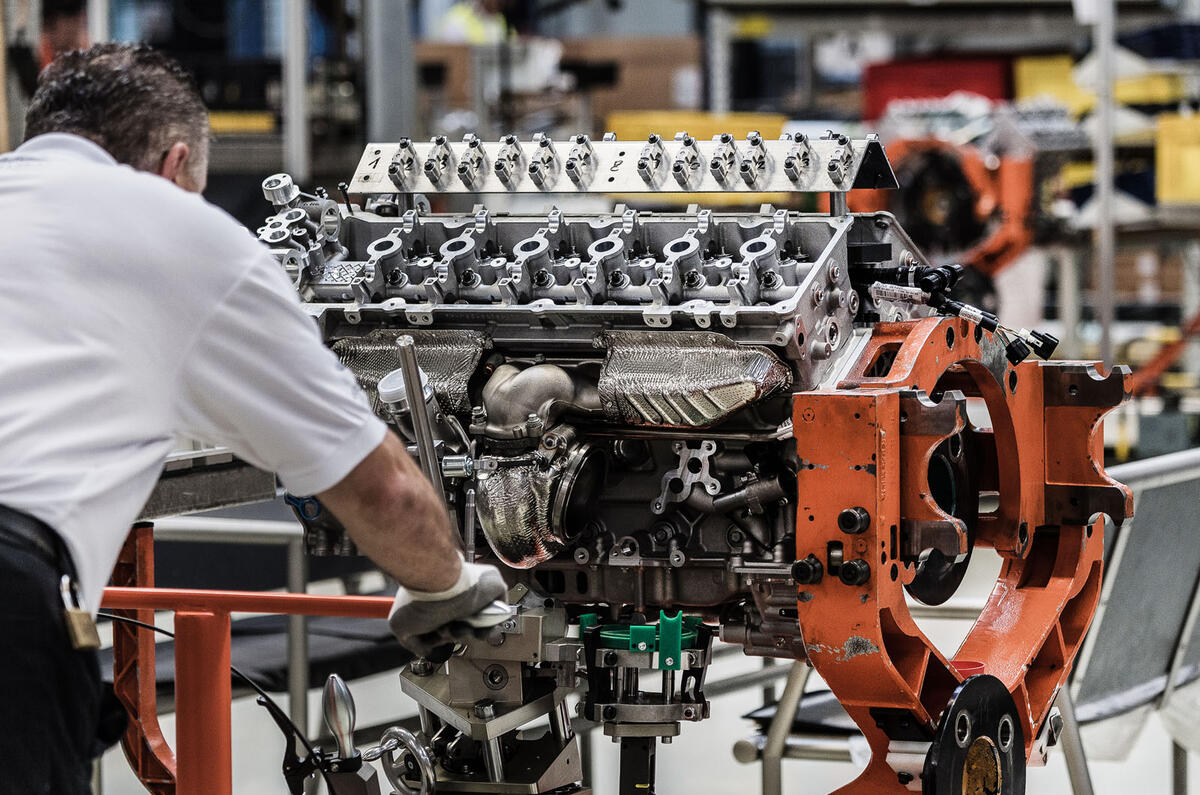

Aston Martin has built the first customer version of its new 600bhp 5.2-litre twin-turbocharged V12, which will power the new DB11, high-end Vantage models and possibly a new flagship SUV and Aston Martin Lagonda saloon for at least a decade, and maybe up to 15 years.

We've now driven the 2016 Aston Martin DB11. Read the review here.

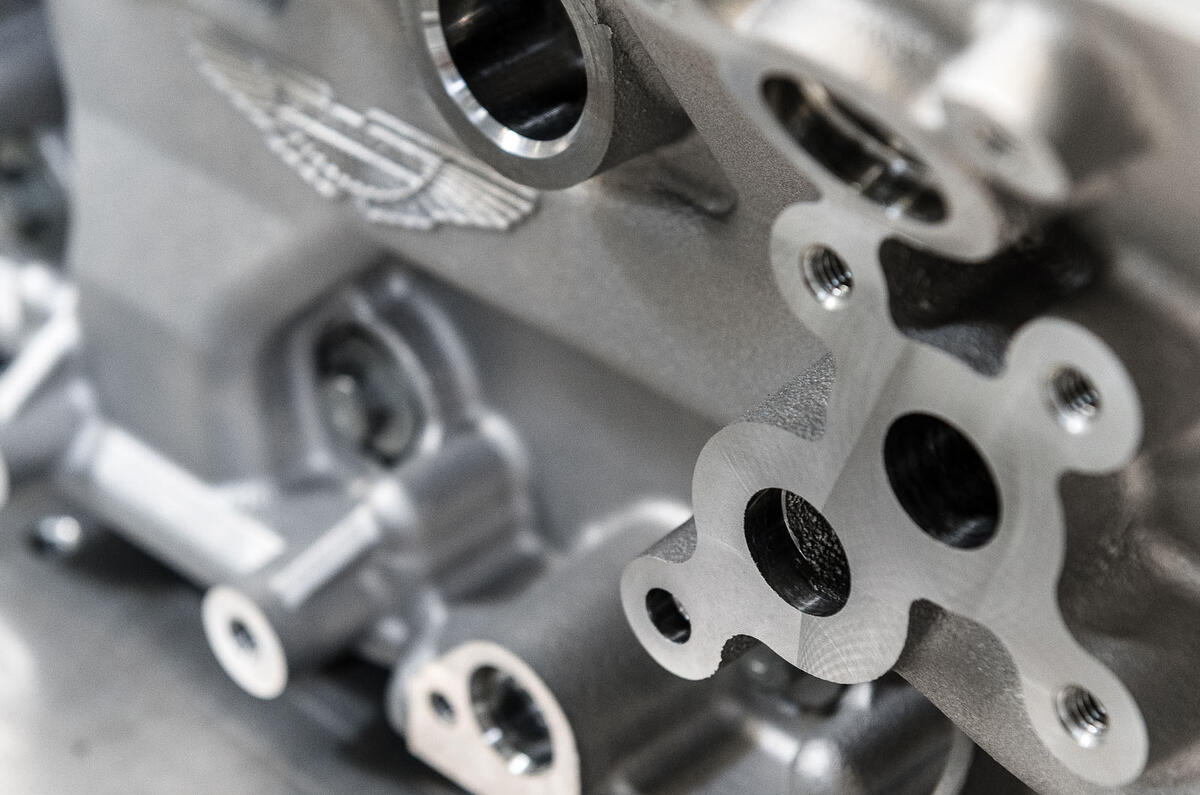

Designed-new from the ground-up in Britain, the alloy block/head design is known internally as the AE31 and replaces the 13-year-old AE28 design – the 6.0-litre V12 that helped Aston re-launch in 2003 under Ford ownership with the DB9.

“This is job one for the next-generation of V12 engine that will be at the heart of Aston Martin’s second-century strategic plan for expansion,” said CEO Andy Palmer.

Palmer signed the engine and said that it would be fitted to the first DB11 production car, which may be retained by the factory, although an alternative plan could see it allocated to a customer.

Aston’s head of powertrain Dr Brian Fitzsimons oversaw the AE31 project, which started in design in summer 2012 and moved rapidly from a test firing in October that year to the production green light in January 2013.

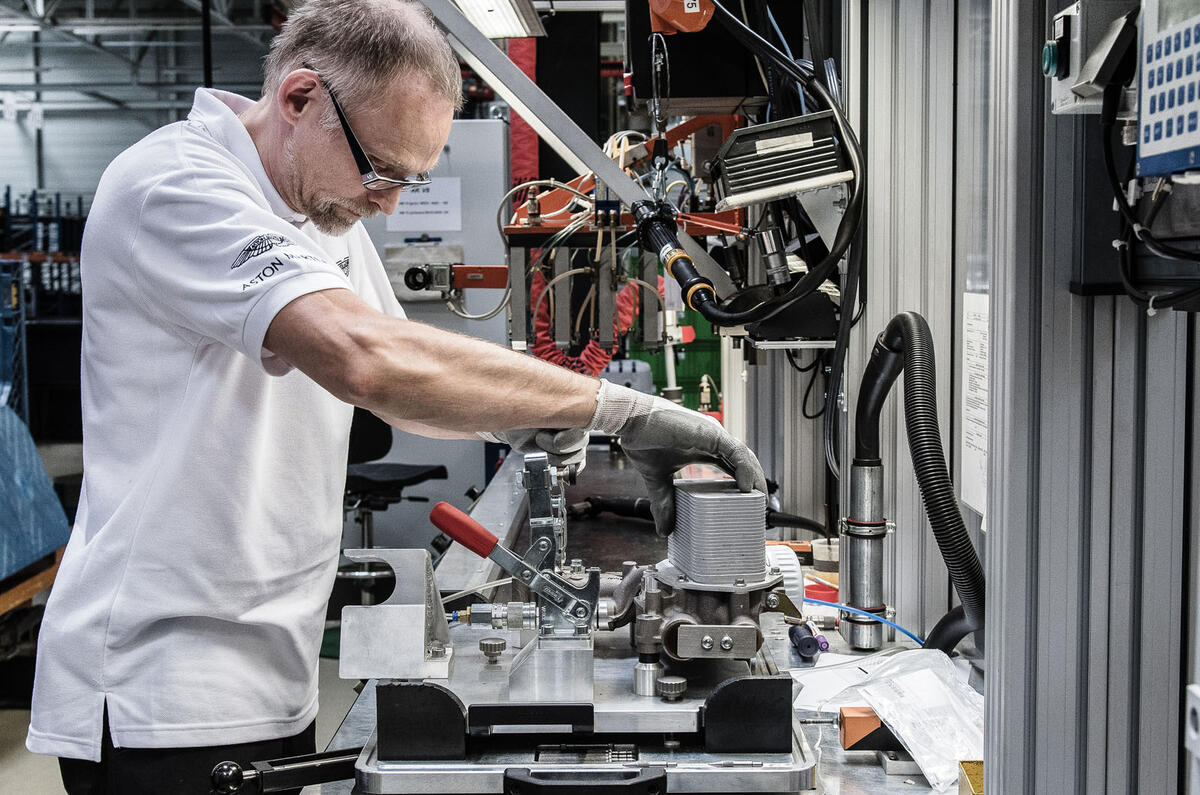

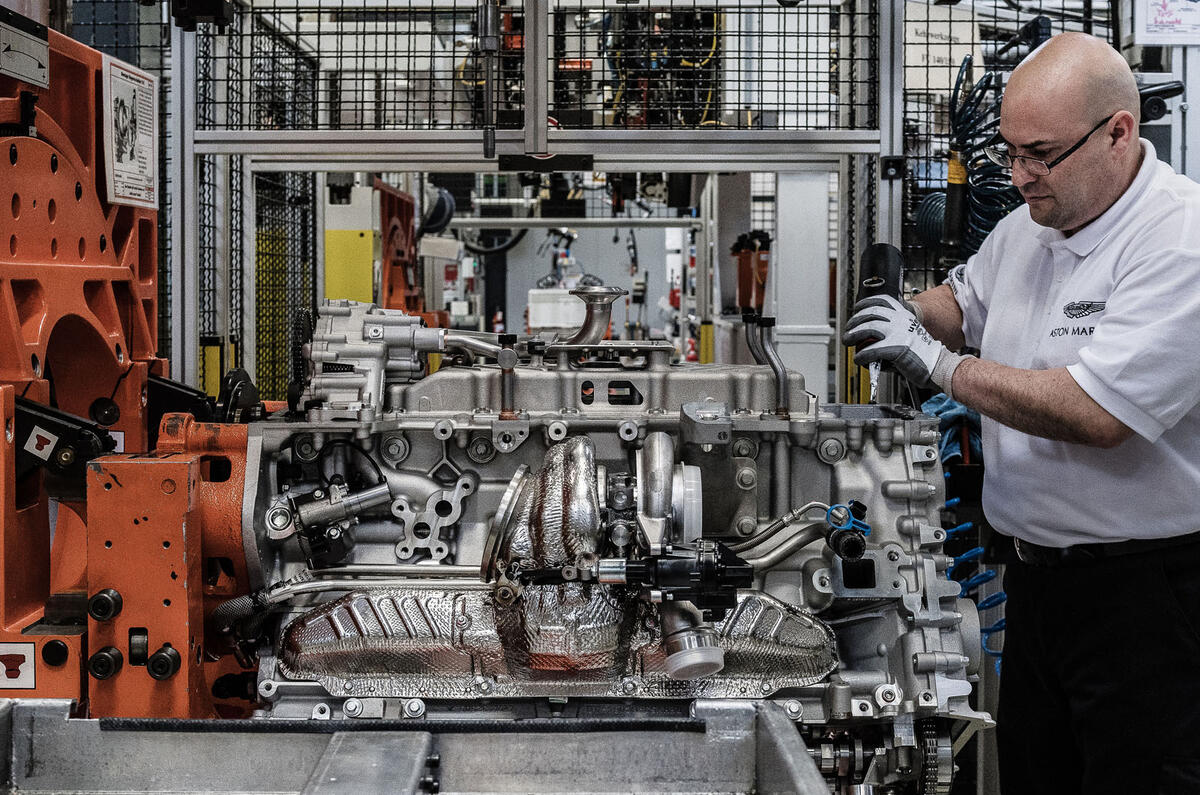

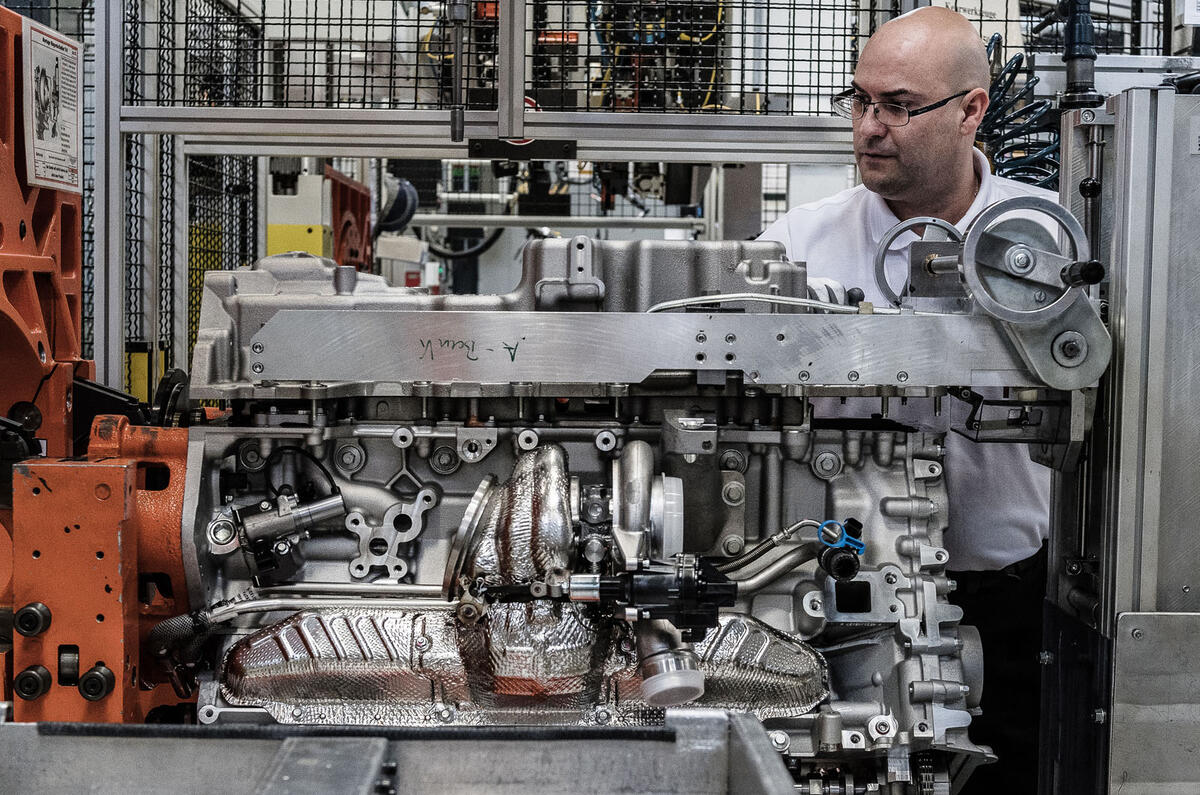

Aston continues to make the engine at a Ford-staffed factory inside its factory at Niehl, Cologne.

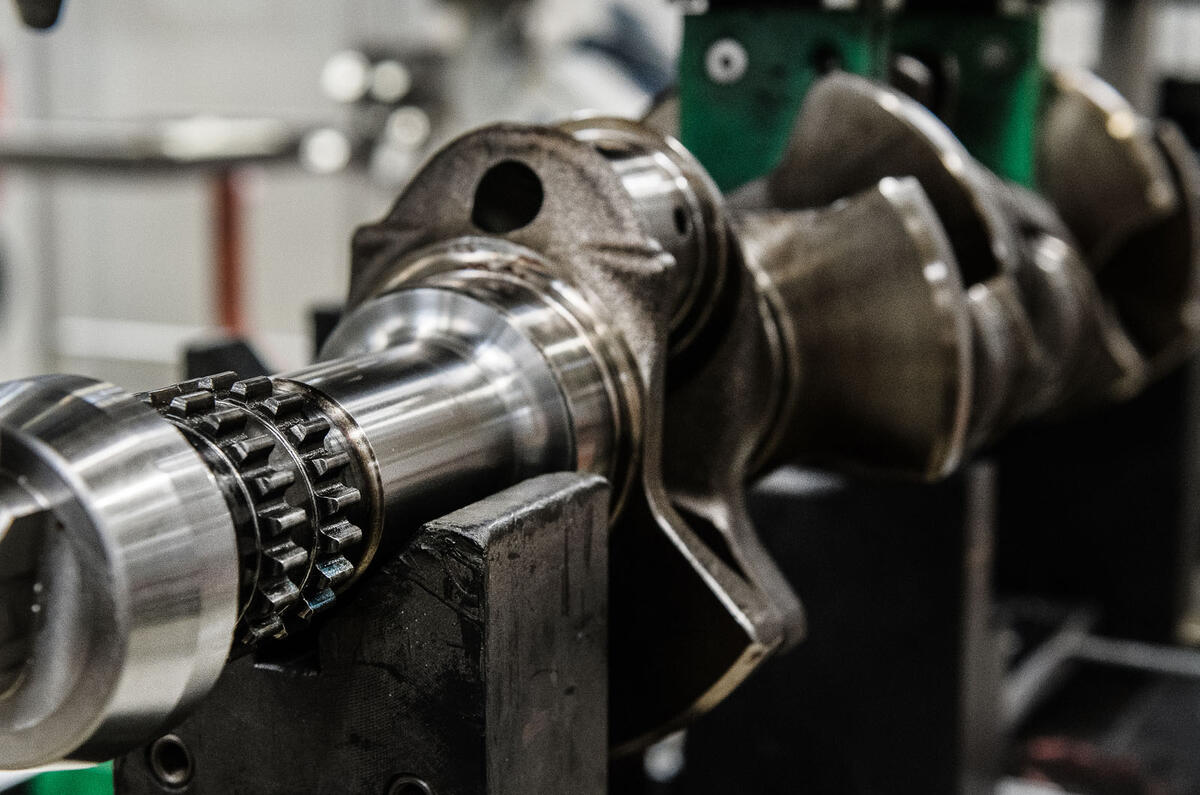

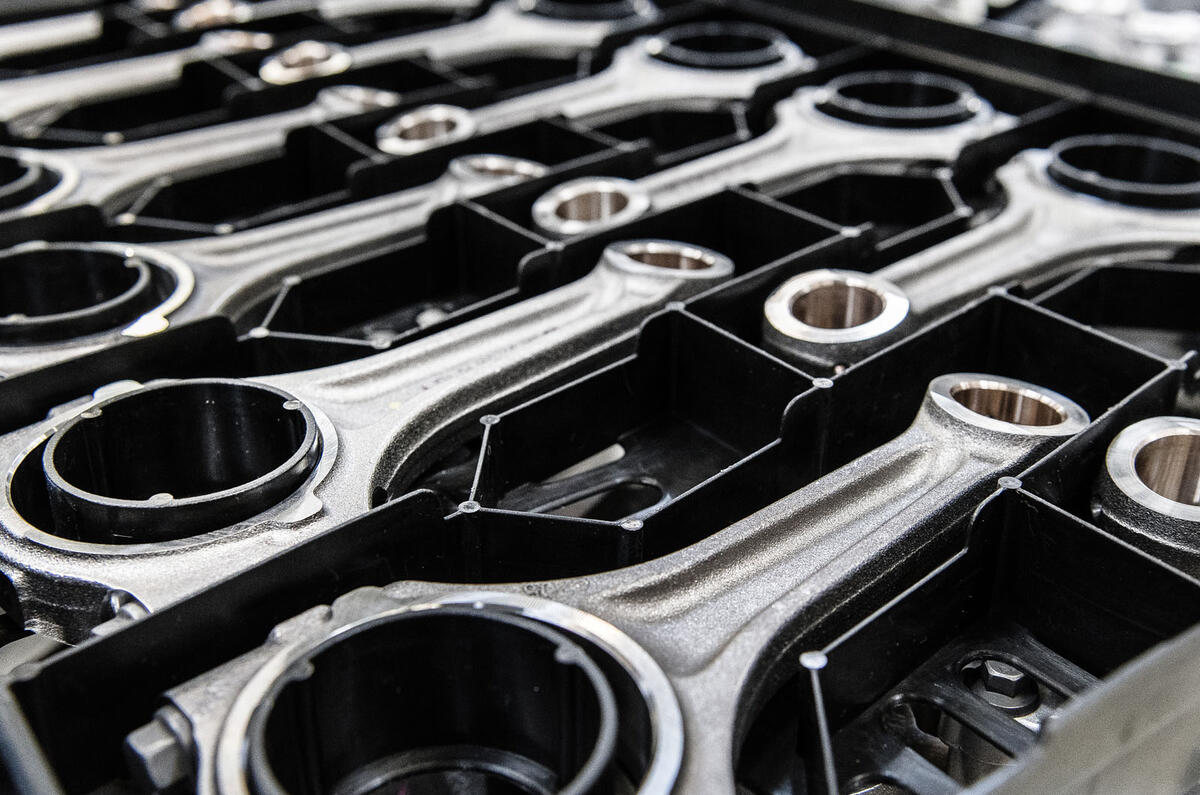

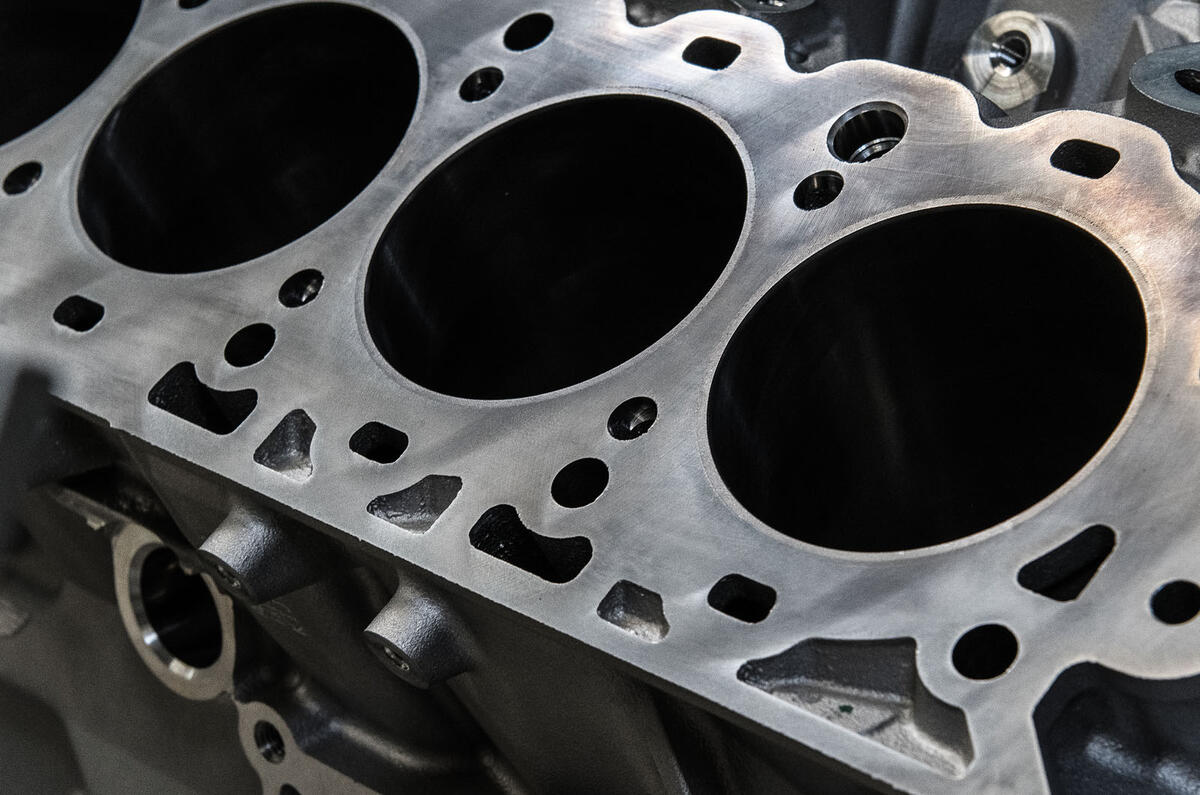

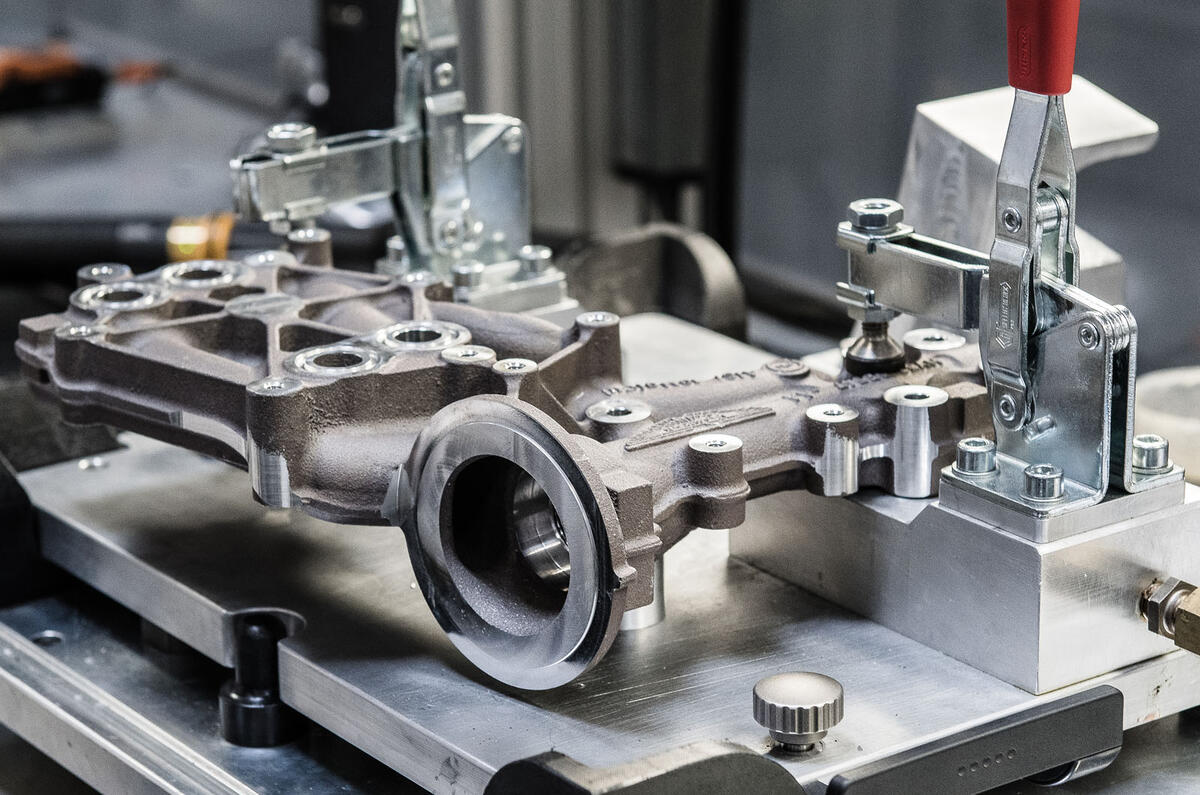

The AE31 uses the same 21.5mm bore offset and 60deg vee-angle as the previous-gen 6.0-litre, to ease manufacture, but all the key components are redesigned.

The bore is the same at 89mm – another dimension set by the manufacturing equipment – but the stroke is much shorter at 69.7mm – hence the reduction in swept capacity.

Peak power is 600bhp at 6500rpm and peak torque 700Nm at 1750rpm.

Fuel economy and emissions figures in the DB11 are still being finalised, but Fitzsimons is talking about 255g/km – 10g/km below the 265g/km target – with more reductions to come.

"I’m determined to keep the team working on the engine. And I think we might be able to get it below 250g/km," he said.

The new V12 retains conventional fuel injection and not direct injection because of worries over increased particulate output with DI petrols. “We’re just not sure where legislation is going on emissions, so we have stayed away from GDi-type technology,’ said Fitzsimons.

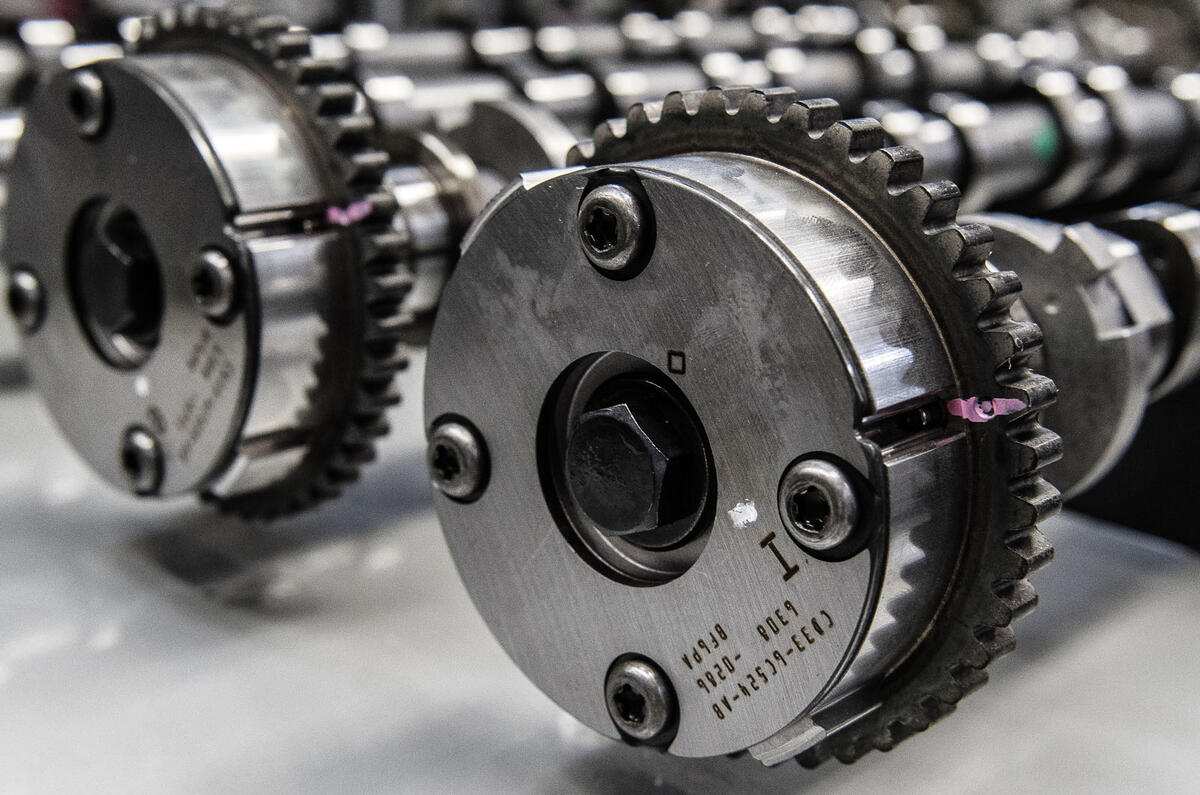

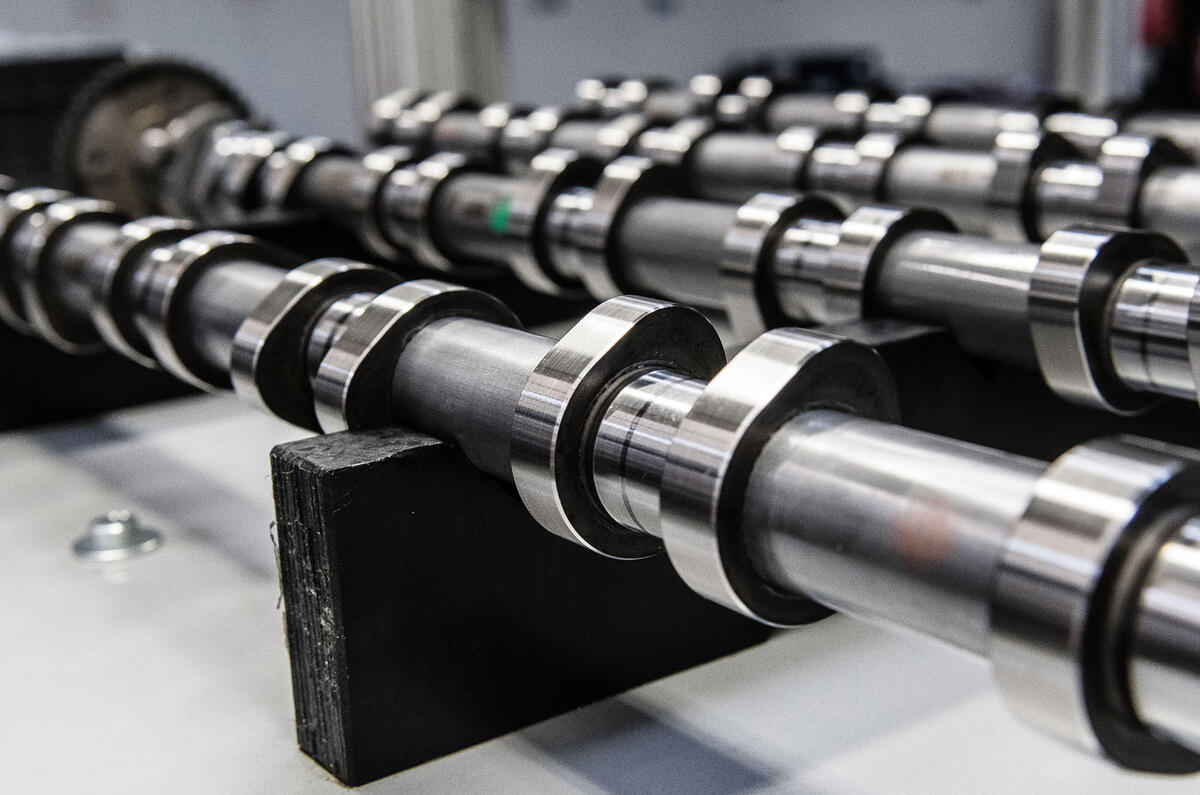

Aston says three parts are carried over: the camshaft roller-rockers, the cam covers and the variable-valve timing device that alters the cam timing.

During development Aston used test cells at the road car division of Ilmore Engines, at Brixworth, next to the Mercedes-AMG F1 facility. “They have really excellent equipment and test cells and we needed that sort of service,” says Fitzsimons.

During development Aston also used AVL, the German engineering consultants for emissions testing and proving.

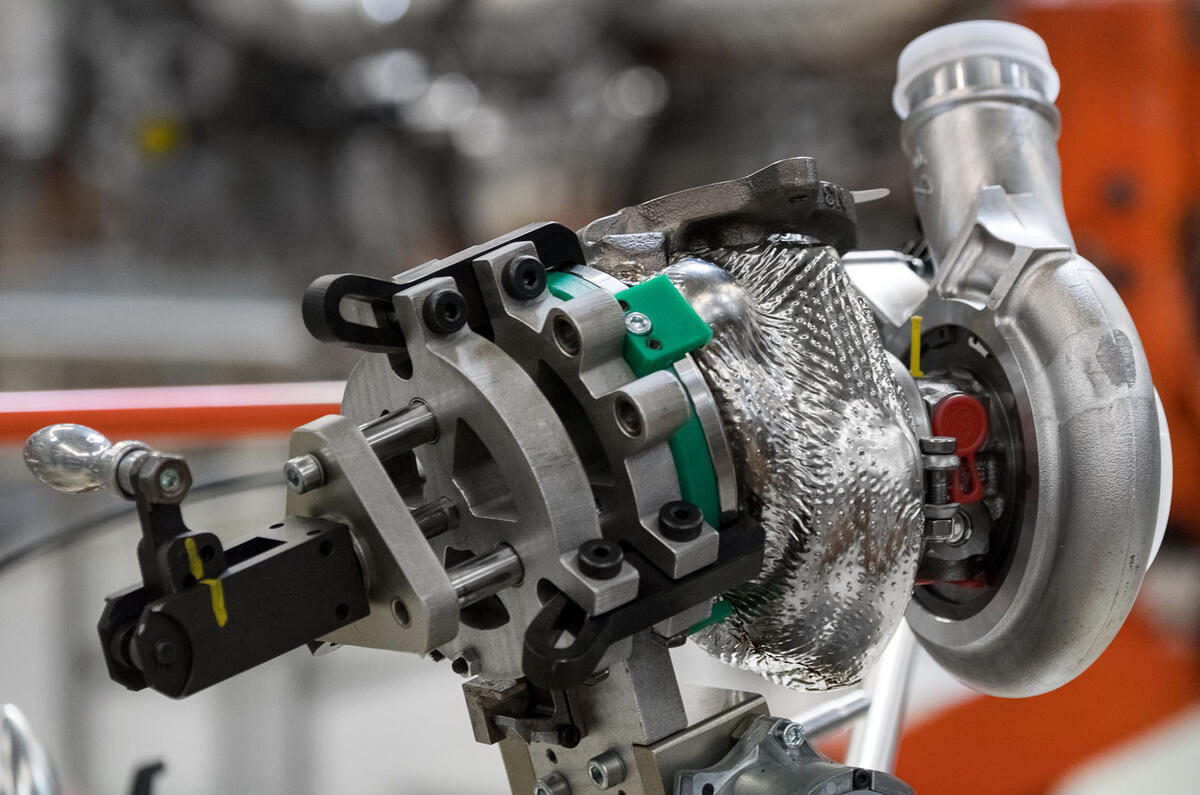

The new V12 would have been 35kg heavier than the outgoing 6.0-litre because of the addition of two twin-scroll turbos and the associated plumbing and intercooler.

Join the debate

Add your comment

A pity the engine is made by Ford in Germany

What about a 300bhp 2.6 6-inline?

A34 wrote: While V12s are all

Because switching to lower-profit, higher-volume is a risky strategy purely in business terms even if it didn't risk alienating the core customers due to loss of exclusivity. Besides, Aston has no spare production capacity and no sugar daddy to assist development costs of a Boxster-like car. So they'd be bankrolling the entire venture themselves at a hope of increasing profits a bit, in exchange for a lot of investment, no guarantee of success and a risk of loss of existing profits.

Particulates...

I wonder if the next "VW" type scandal will involve the modern small turbo DI petrol engines...