For most of its life, Lotus Design consisted of an unfeasibly small group of highly talented individuals tucked away in tiny premises adjacent to Hethel, the Lotus headquarters that company founder Colin Chapman opened in 1966 on a wartime airfield south of Norwich.

Their traditional task was to produce simple, light and track-focused sports cars that followed the hallowed 74-year Chapman tradition, imaginatively using proprietary parts because they were good, cheap and plentiful. Lotus has always had a ‘beat the system’ culture. Why use two parts when one can do two jobs? Why build your own engines when existing units work fine at a fraction of the cost?

Lotus cars have been cheap, too, if you judge their capability against that of big-company rivals. Most were so good that a loyal body of buyers (never enough) was prepared to overlook traditional brand shortcomings in areas like access, cabin design, control layout and day-to-day practicality. They enjoyed the driving and felt good about supporting a deserving cause.

In a corporate sense, the Lotus story has been a long succession of under-resourced group managing directors (of very mixed tenure and ability) battling to satisfy uncertain owners and a motley band of dealers who believed they were making their own sacrifices to keep Lotus on the rails. Sometimes the most urgent struggle was to pay the workforce at the end of the week.

That all changed six years ago when Chinese company Geely came into the ownership picture. Its management of the car makers that it had already acquired, principally Volvo, made it rapidly apparent that of all the global giants Lotus could have joined, this was the best. High targets would be set, but the management would be unobtrusive. And for the first time in nearly 70 years, adequate investment would be available.

Geely has already rebuilt Hethel and revolutionised the sports car manufacturing process, spending £100 million on a plant that won’t only build the just-launched Lotus Emira – in unprecedented numbers as great as 9600 per year on two shifts – but also its electric replacement, currently called the Type 135, arriving in 2026.

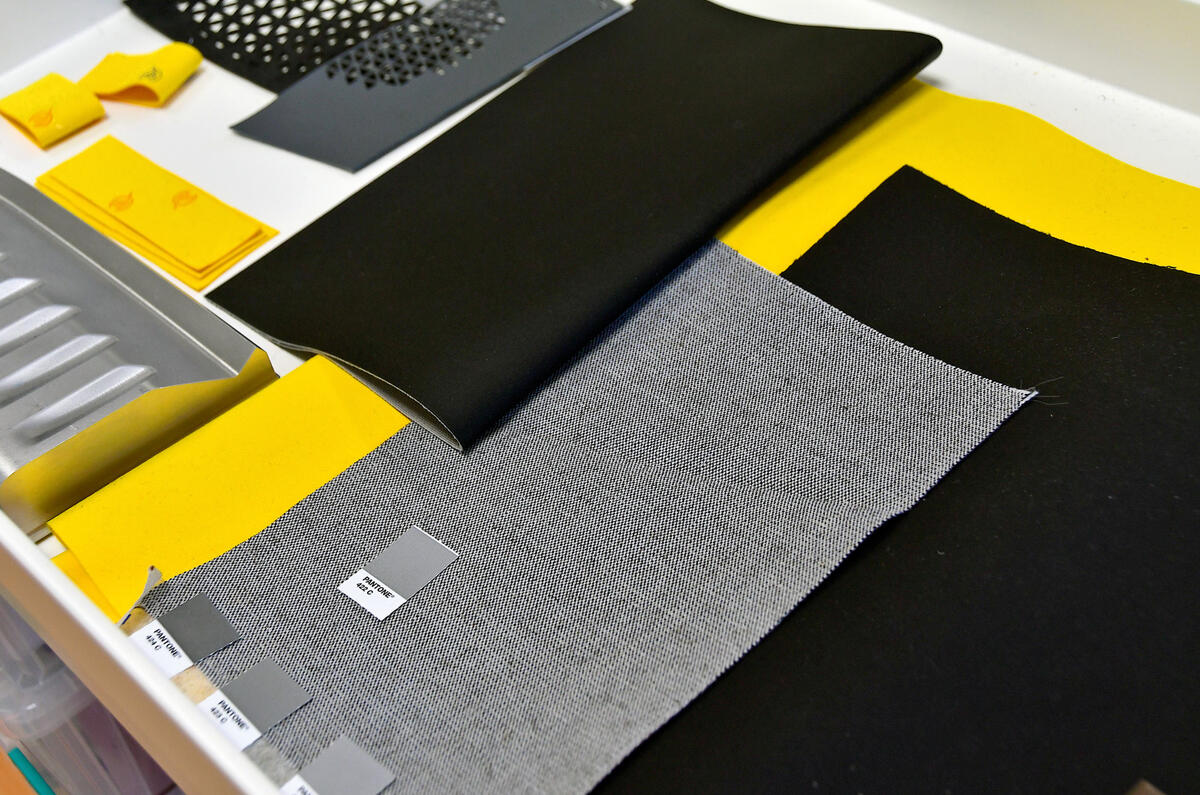

Less obvious but arguably even more significant is the fact that for the past three and a half years, Geely has had a design facility on the northern outskirts of Coventry working on the much bigger-scale, China-based Lotus Technology business. This is an enterprise that will eventually fill a 150,000-cars-per-year factory in Wuhan with three Lotus-badged EVs that aren’t sports cars but (the company insists) will nevertheless uphold Chapman principles so long as you’re prepared to interpret them liberally.

Add your comment