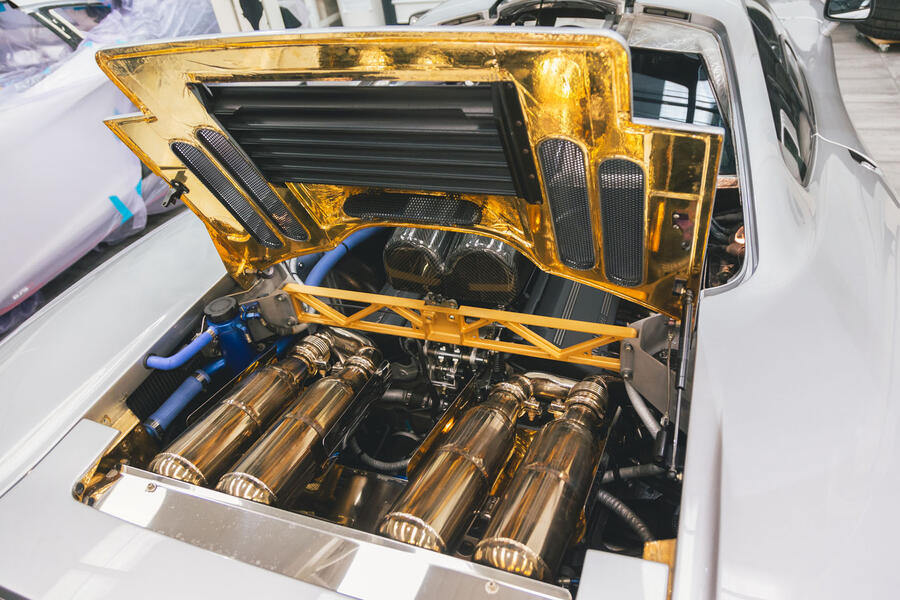

“Compared to many cars, these are a mechanic’s dream,” says Pani Tsouris as we both peer past the dazzling gold heat protection and highly polished titanium exhausts to the vast V12 nestling deep in the engine bay.

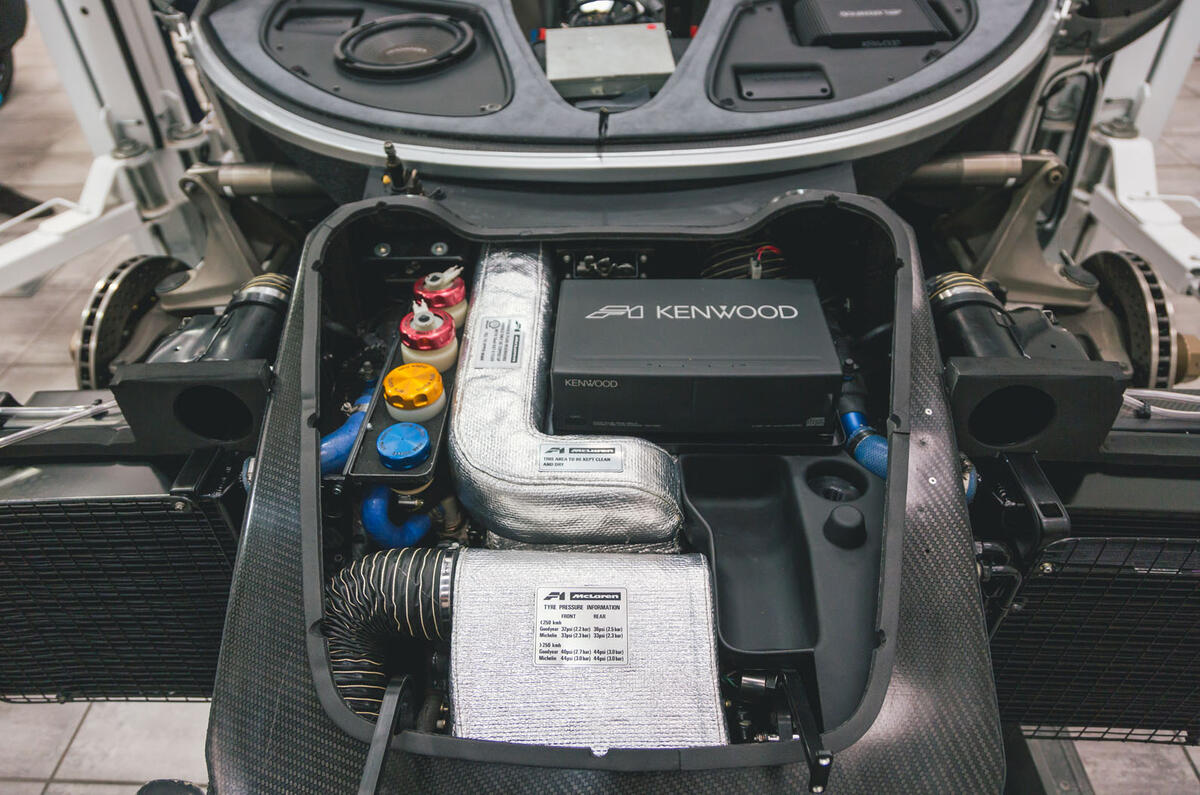

“Everything has been properly thought through. The fuses are easy to access, all the fluid reservoirs are bundled together in the nose and there’s space – you can get to all 12 spark plugs and the air and oil filter.”

Now I wasn’t expecting to hear this. I was prepared instead for tales of the McLaren F1 being a proper prima donna, requiring a tortuous service schedule and a technician with double-jointed wrists and an ability to see through steel. However, if anyone can set me straight then it’s Tsouris. He’s lead F1 technician at the McLaren Special Operations (MSO) Heritage division, and he’s been working on the iconic supercars for more than 15 years, here at a large, nondescript warehouse on an industrial estate in Woking, Surrey.

Autocar's exclusive McLaren F1 road test: 25 years on

This is where most owners bring their cars to be worked on. There is a ‘flying spanners’ service that will send a mechanic to a car anywhere in the world, but increasingly those who run the cars want them to go ‘home’ for a check up, or even a full restoration. And when you step inside it’s not hard to see why. On the day we visit the immaculately kept workshop there are five F1s on the ramps, including a road-registered 1996 F1 GTR in Fina colours with period factory racing driver Steve Soper’s name on the door.

So just what does it take to keep an F1 running? Over to Heritage manager Thomas Reinhold, a man with a head so full of McLaren facts it’s surprising there’s room left for much else. “When it was new the normal service intervals were nine and 18 months,” he explains. “But these days we tend to see a car once a year or so.”

Join the debate

Add your comment

ya

I guess if you can afford to

indeed

and rebuilding the rolls-royce engine of a boeing 747 is just a few connectors and some spannering