The view that an EV is no better than a glorified milk float with all the technical appeal of a washing machine is being put in its place.

As manufacturers begin to fine-tune EV motors and drivetrains to get improved range and performance, it becomes clear that the difference between electric and ICE may not be as great as many assume.

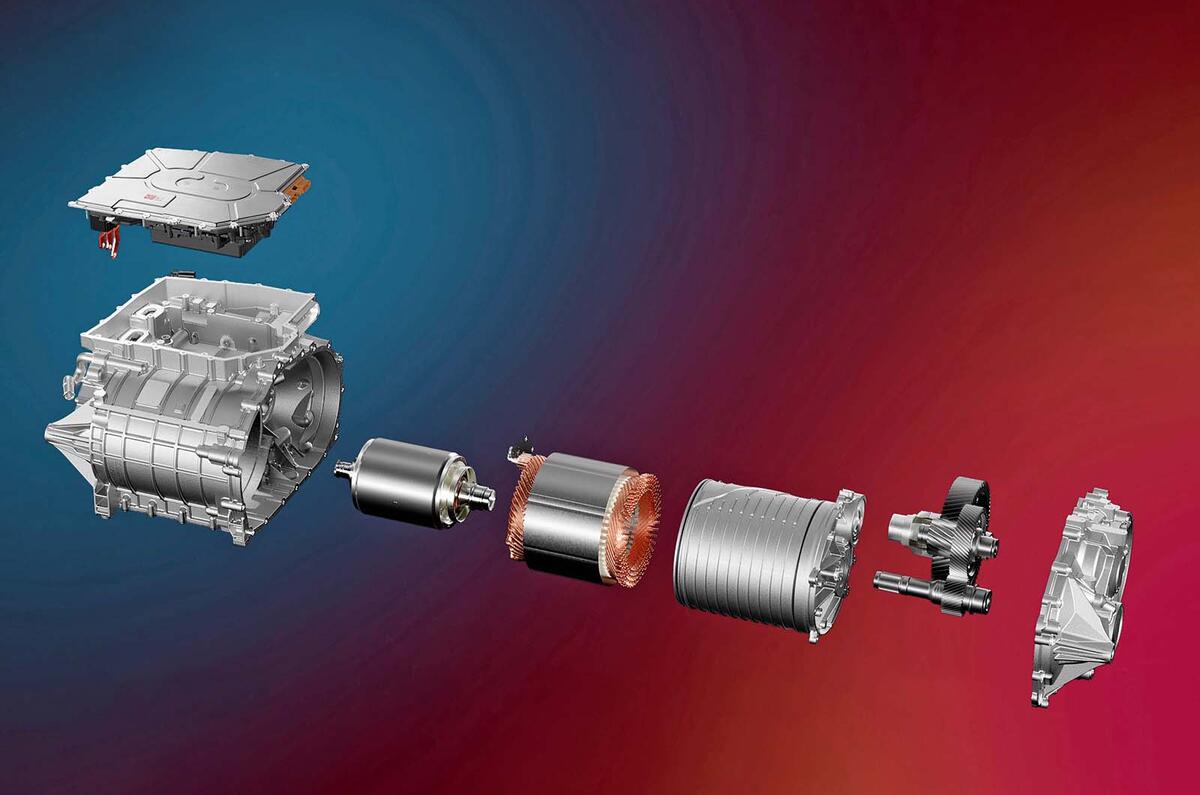

Volkswagen has just announced its new drivetrain for the MEB vehicle architecture with a systematic series of design tweaks aimed at getting more for less. Or to put it another way, finding more torque, more efficiency and better range while fitting into the same space.

Intended for the next generation of the ID family, the new, rear-wheel-drive APP550 drivetrain generates 281bhp and 406lb ft of torque at the final drive, depending on the gear ratios in the single-speed reduction gearbox.

Torque is affected by gearing so, for example, reducing the gear ratio multiplies the torque. It’s why in a conventional ICE car with a manual gearbox, it may be possible to spin the wheels in first gear but not in second.

It’s also why you have to change down to climb hills. So VW’s quoted 406lb ft of torque is not to be confused with torque output from the motor shaft: it’s what is being sent to the driving wheels, having passed through the reduction gearbox.

The increased all-round performance of the drivetrain was achieved in much the same way as it has been for over 100 years with combustion engines: by finding ways to extract more mechanical power from the same amount of energy. The difference is the energy is in electrical form and not heat from burning fuel, so how was it done?

VW uses permanent magnet synchronous motors that follow the tried and trusted approach of a solid rotor with embedded magnets, surrounded by the windings that generate the rotating magnetic fields. The magnets in the rotor slavishly follow the fields and so the rotor spins. It also keeps pace with the fields so its speed is synchronised with them, hence the term synchronous.

The windings (collectively called the stator because it doesn’t move) have increased in number and the wire used has a larger cross section (it’s thicker). At the same time, the rotor has more powerful magnets and the drive system has been beefed up to withstand the much higher torque.

The inverter – the brain that converts electricity between DC (battery) and AC (motor) – has been redeveloped. It can handle higher current and the software has been improved so the motor converts electricity into mechanical energy more efficiently.

Instead of using a power-sapping electrical pump, the system self-cools by allowing the gear wheels and other components in the transmission to distribute the oil without one, and once heated, the oil is collected and cooled.

So by scrutinising each part of the car’s ‘engine’ and drivetrain and making improvements, engineers have followed a similar approach to engine tuners of yore. Only the energy source has changed.

Join the debate

Add your comment

As I understand it even the worst electric motors have an efficiency better than 90%, so there isn’t much scope for improvement beyond weight reduction.

Compare that with combustion engines which universally have had very poor thermal efficiency especially under part load and so the gains here have been much more significant.

The big bugbear is that EVs, while incredibly efficient at converting electrical energy into mechanical work, still waste a massive amount of energy in merely transporting their batteries.

LP you're sounding more desparate with every anti EV post. This article isn't about ever improving batteries it's about EV drivetrains.

You try to make it sound that EV motors are inefficient despite running at 95 percent efficient, ICE can only dream of that figure.

ICE have had a 150 years of serious development, EV cars around 10, guess what has the larger scope for improving.

I'm not anti EV at all and I love the fact that their electric motors are so efficient and likely even more so in the future. And battery developments do sound very promising indeed.

But I'm not blind to the fact that existing batteries are extremely heavy, bulky and expensive, the charging infrastructure isn't what it needs to be - and existing EVs are now starting to depreciate heavily from their initial high cost.

For a business user, I accept the EV advantages vastly outweigh these issues. But for myself, a low mileage private user I can't yet justify the change.

Believe me, I have solar panels producing vast amounts of free energy that I would love to use in an EV, but the arithmetic unfortunately does not add up!