Rimac Technology, the Croatian car maker’s stand-alone engineering division, will “build Rimac out from its position as a start-up” by revolutionising the EV world with solid-state batteries, more power-dense packs, high-performance powertrains and more, its chief operating officer, Nurdin Pitarevic, has told Autocar.

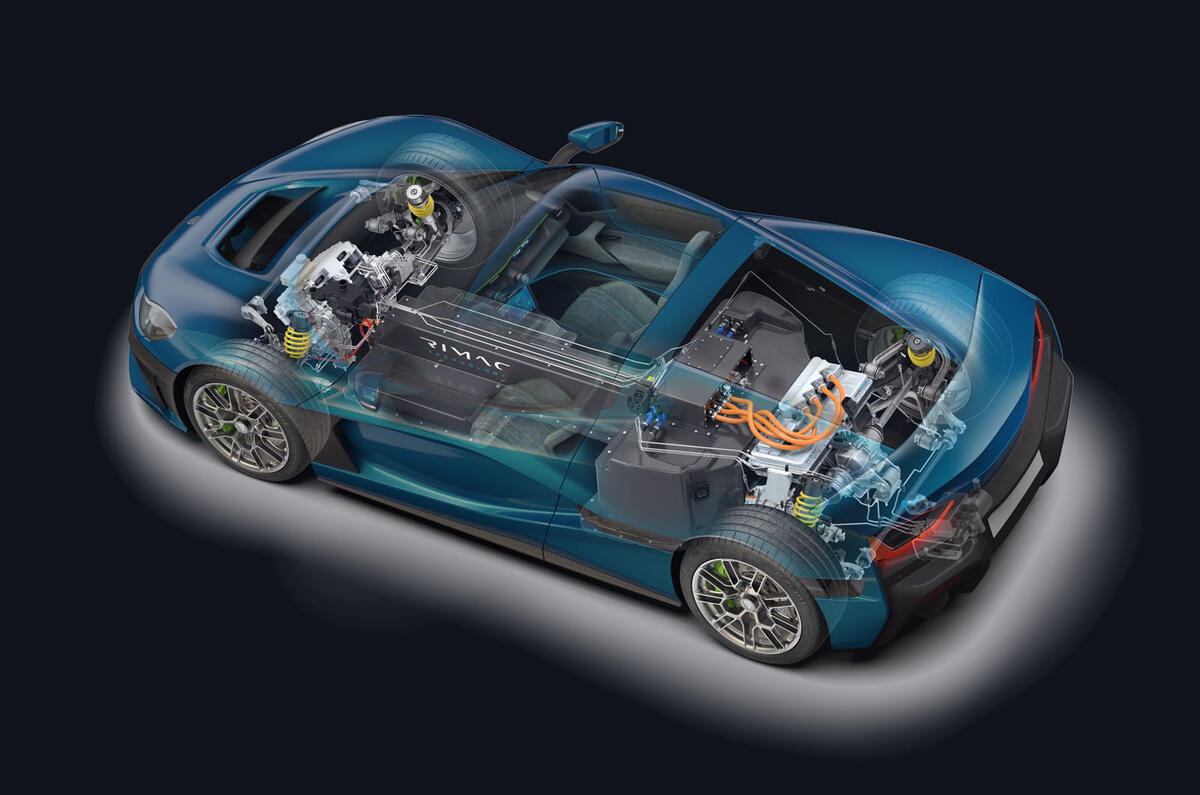

A company that was spawned from its Rimac namesake in 2022 following the deal with the Volkswagen Group to create Bugatti Rimac, Rimac Technology has been developing EV tech for the Croatian hypercar maker and third-party manufacturers.

This has ranged from small hybrid battery systems to full rolling chassis for clients that include everyone from large global manufacturers to low-volume firms. It also develops electronic systems, electric drive units and user-interface components.

Solid-state is on the way

In an exclusive Autocar interview, Pitarevic – Rimac Group CEO Mate Rimac’s second in command – explained that the company is already well advanced with a new range of solidstate batteries. It is working on them with cell maker ProLogium and composite materials experts at Mitsubishi and it aims to put them on the market late this decade.

Pitarevic said he expects testing of the batteries to begin very soon and his “wish would be” that they would have their first application (in what he terms mid-volume production) in a new Bugatti model, due in 2030.

He expects the cost of the new-tech batteries to reach parity with current NMC (standard cell) types by 2035, though he insists Rimac has no wish to make solid-state batteries in big enough volumes to power conventionally priced cars. Perhaps if a bigger OEM were interested in licensing their technology to make batteries for their own cars, they would “look at it”, he said.

A prototype of the solidstate battery has a capacity of 100kWh and is claimed to be between 20% and 30% more energy dense than a conventional battery for the dimensions. It’s also around 30kg lighter, mainly because of weight saved by the light but ultrastiff composite housing contributed by Mitsubishi. The pack can also accept charge much more quickly and in a safer manner.

Although Rimac’s reputation rises ever higher as it develops as a major supplier of premium high-tech components, the company is unlikely to make cars beyond the slow-selling Nevera, according to Pitarevic.

Rimac’s focus today, he said, is on thinking like the end user of an electrifi ed car when it designs EV components. It targets three things: maximising range, improving safety (especially fire safety) and slashing charging times. All three are properties of the solid-state batteries it is rushing to develop.

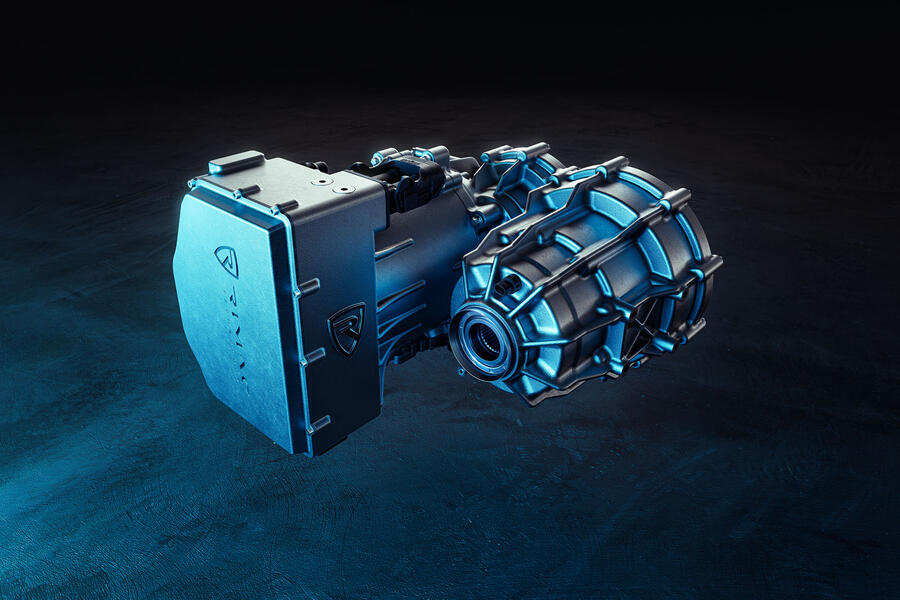

E-axles for EVs and hybrids

The new e-axles, which combine electric drive motors, gearboxes and control electronics in a variety of light and compact packages, can put out between 200bhp and 470bhp in layouts to suit front-wheel drive, rear-wheel drive and four-wheel drive. Pitarevic also stresses the units’ suitability to both hybrids and pure EVs, and cites BMW, Porsche and Saudi Arabian EV start-up CEER as customers so far – as well as many others that remain anonymous.

This all comes as Rimac prepares its new €300 million (£261m) manufacturing campus, comprising 95,000m2 of production space in Zagreb, Croatia, to create tens of thousands of these tech components every month.

Join the debate

Add your comment

Top tip, tone down the boasting of saving 30kg with a 100kwh solid state battery and even that's down to housing. It's not that'll bigger a deal on a 600kg battery.

So, when's the first 300mph road car going to appear?